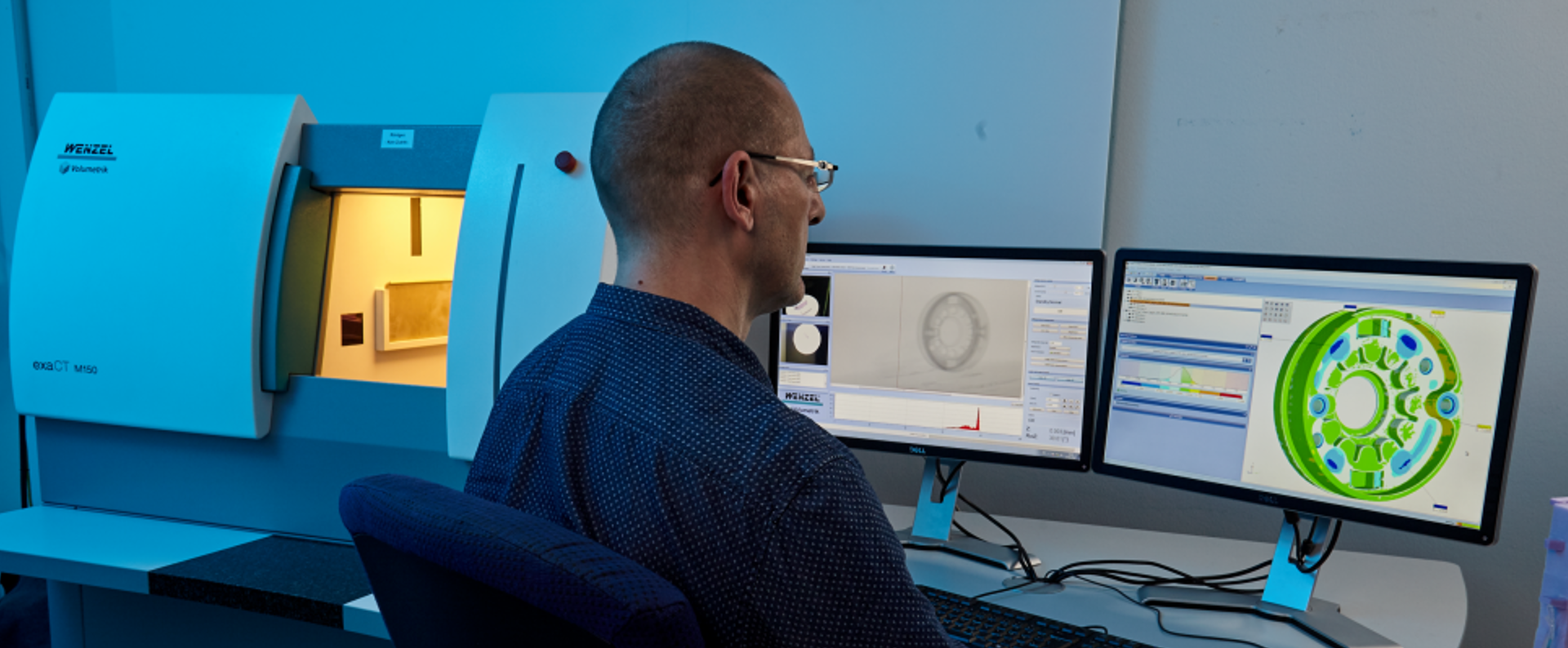

MENTOR has provided specialist LED-based lighting solutions for many years, across many different market sectors. Managed by an experienced project management team, our customers’ ideas are turned into custom lighting solutions in five stages: from the technical concept to engineering, visualisation and tool design to the production of the finished component. This is guaranteed by a team of highly qualified experts, unsinge the latest hardware and software equipment, advanced tool construction, an economical and quality-driven production with locations in Germany and abroad as well as efficient logistics.

Solutions from a single source - from the concept to the final solution

Concepts

Consultancy · Light source · Optics concept

Thermo-concept · Special features

Working closely with our customers, the fundamental concepts are developed and the exact design requirements are defined. The most suitable LED light sources are chosen, the optic concepts are defined and careful consideration is given to appropriaten energy and thermal management.

ENGINEERING

Optical design · CAD / CAL · Construction

Definition sensors, Light source, Material

During the development phase, specific component features are defined: reflective or refractive optic design; sensor design, light source design; CAD design etc.

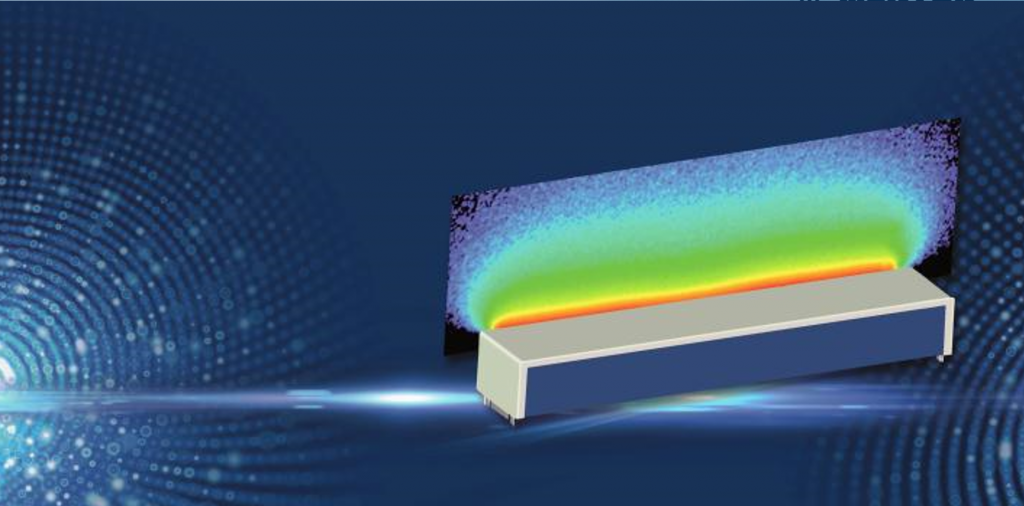

VISUALIZATION

Light measurement · Light simulation · Prototype

tool for light guides · Rapid prototyping

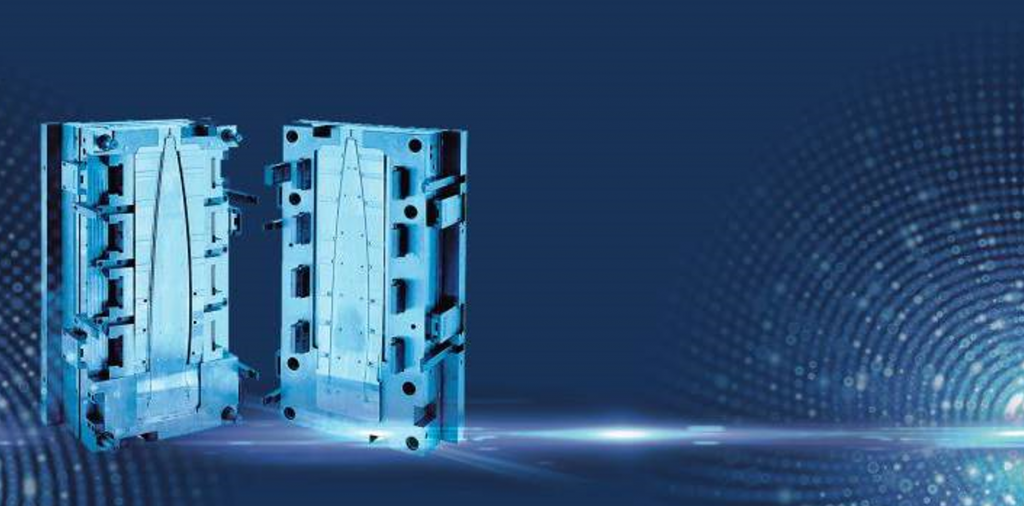

TOOL DESIGN

Tool-making · Ultra-precision machining

for high-performance optics

We design and produce the injection moulds in our own tooling factories. For complex, high-performance optics, the moulds are then precision-machined using ultra-precision machine tools.

PRODUCTION

Injection moulding · Module assembly · Quality

management · Packaging · Logistics

MENTOR provides complete lighting solutions. These start with single or multiple component injection moulding and include enhancements such as reflectors and other nonoptic components.

The production line is continuously monitored for QA, using a fully-certified quality management system.